0102030405

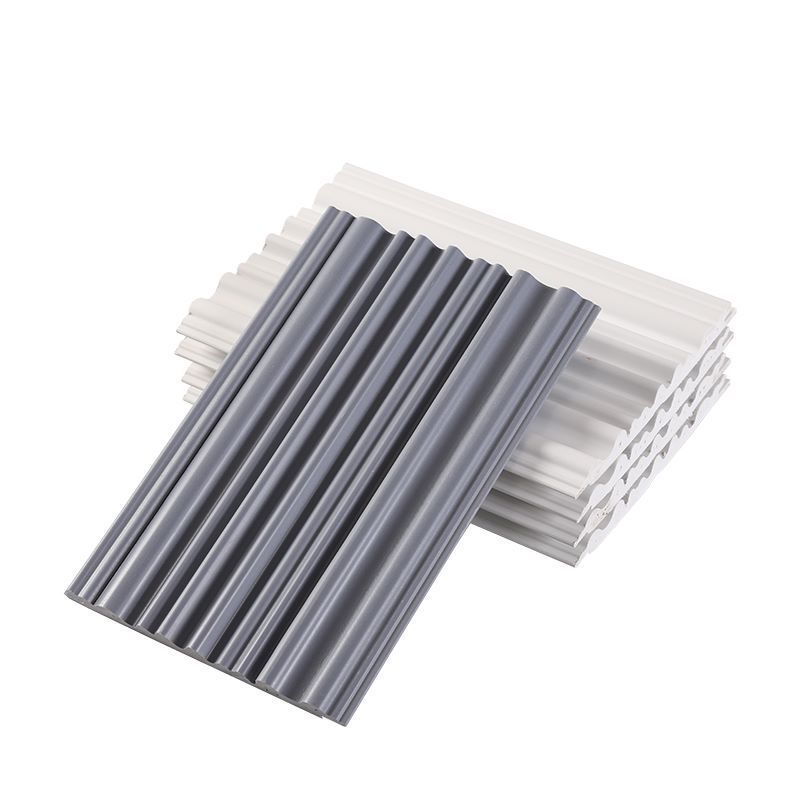

Wpc wall panel eco-friendly Fluted Composite Cladding Indoor Decoration

product description

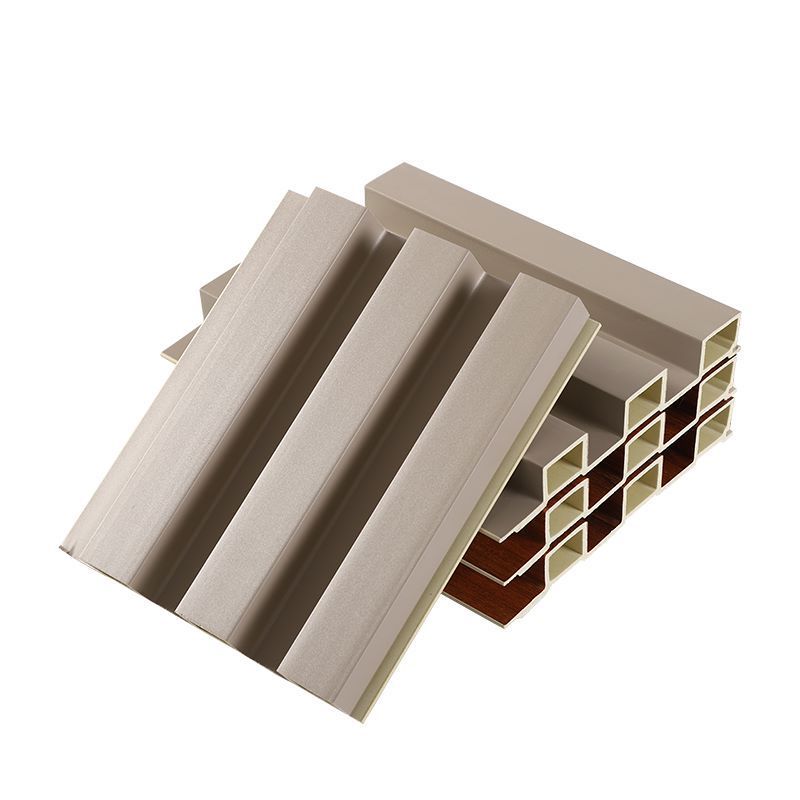

WPC wall panel is a product of Wood-Plastic Composites. It is made of polyethylene, polypropylene, polyvinyl chloride and other materials instead of traditional resin adhesives, and is mixed with more than 50% of waste plant fibers such as wood powder, rice husk, and straw. This material is produced through plastic processing processes such as extrusion, molding, and injection molding, and is ultimately formed into sheets or profiles. WPC wall panels are widely recognized and used in the construction industry due to their versatility and durability.

Easy processing

WPC wall panel has the same processing performance as logs, which can be nailed, drilled, cut, bonded, and fixed with connectors.

Eexcellent performance

WPC wall panel has better physical performance than log, better stability than wood size, will not produce cracks, warping, no wood scar, twill, film or composite surface layer can be made of a variety of colorful products, so no need for regular maintenance.

Strong function

WPC wall panel has fire prevention, waterproof, noise reduction, corrosion resistance, moisture resistance, no moth, not long fungus, acid and alkali resistance, harmless, no pollution and other excellent performance, low maintenance cost.

The appearance is beautiful

WPC wall panel in use has a similar wood appearance, longer than the log life, good toughness, energy saving. Strong product quality, light quantity, heat preservation, smooth and smooth surface.

Since WPC wall panels do not contain substances harmful to the human body and are a green and environmentally friendly building material, they can be widely used in hotels, hotels, schools, hospitals, residential buildings, office buildings and other types of buildings to meet the needs of modern architecture. Various needs for indoor and outdoor environments.

product specification

| Place of Origin: | Shandong, China | Model Number: | WPC Wall Panel |

| Product Name: | Wpc wall panel | Application: | Office; hotel; shopping mall; living room, etc |

| Material: | Wood Plastic Composite | Function: | Decoration Material |

| Size: | 159*23/205*15/205*27/170*20mm | Advantage: | Waterproof, fireproof, easily clean |

| Usage: | For indoor wall decoration | Surface: | Sanding Supper Embossing |

| Fire Rating | B1 (Highest level on the SPC Flooring Product) | Payment | 30% deposited, the rest should be paid before delivery |

| Package | Pallet or bulk packing | Delivery time | About 15-20 days for one 20'ctn |

product feature

Environmental Friendliness:

One of the primary advantages of WPC foam boards is their eco-friendly nature. These boards are often manufactured using recycled materials and are themselves recyclable, contributing to sustainable practices and reducing environmental impact. As a result, they are a preferred choice for environmentally conscious individuals and businesses.

Water Resistance:

WPC foam boards are highly resistant to water, making them suitable for both indoor and outdoor use. This water resistance ensures that the boards will not rot, swell, or degrade when exposed to moisture, making them ideal for applications in damp or humid environments.

Low Maintenance:

WPC foam boards require minimal maintenance to keep them in good condition. They are easy to clean and do not require painting, sealing, or staining, saving time and effort on upkeep. This low-maintenance characteristic makes them a practical and convenient choice for a wide range of applications.

Durability:

The composite nature of WPC foam boards provides them with exceptional strength and durability. They are resistant to impact, scratching, and fading, ensuring that they maintain their aesthetic appeal and structural integrity over time. As a result, they are a long-lasting and reliable material for various uses.

Versatility:

WPC foam boards offer a high degree of versatility in terms of design, shape, and application. They can be easily cut, shaped, and molded to fit specific requirements, making them suitable for a diverse array of projects such as furniture, cabinetry, signage, and interior decor.

Thermal Insulation:

WPC foam boards exhibit excellent thermal insulation properties, helping to maintain consistent indoor temperatures and reduce energy consumption. This thermal efficiency makes them an excellent choice for applications where insulation is crucial, such as in construction and infrastructure projects.

Resistance to Insects and Decay:

WPC foam boards are naturally resistant to insects, pests, and decay, unlike traditional wood materials. This innate resistance ensures that the boards remain free from damage caused by termites, ants, and other wood-damaging organisms, resulting in a longer lifespan and reduced need for maintenance.

Appearance and Aesthetics:

WPC foam boards offer a desirable appearance that resembles the natural texture and grain of wood. They are available in a variety of colors and finishes, allowing for customization to suit specific design preferences and aesthetic requirements.

Lightweight:

WPC foam boards are lightweight yet sturdy, making them easy to handle and install while still delivering robust performance. Their lightweight nature contributes to easier transportation, handling, and installation, benefiting both manufacturers and end-users.

Fire Retardant Properties:

Many WPC foam boards are designed to be fire-retardant, offering enhanced safety in applications where fire resistance is essential. This feature makes them a reliable choice for use in construction, interiors, and other environments where fire safety is a concern.

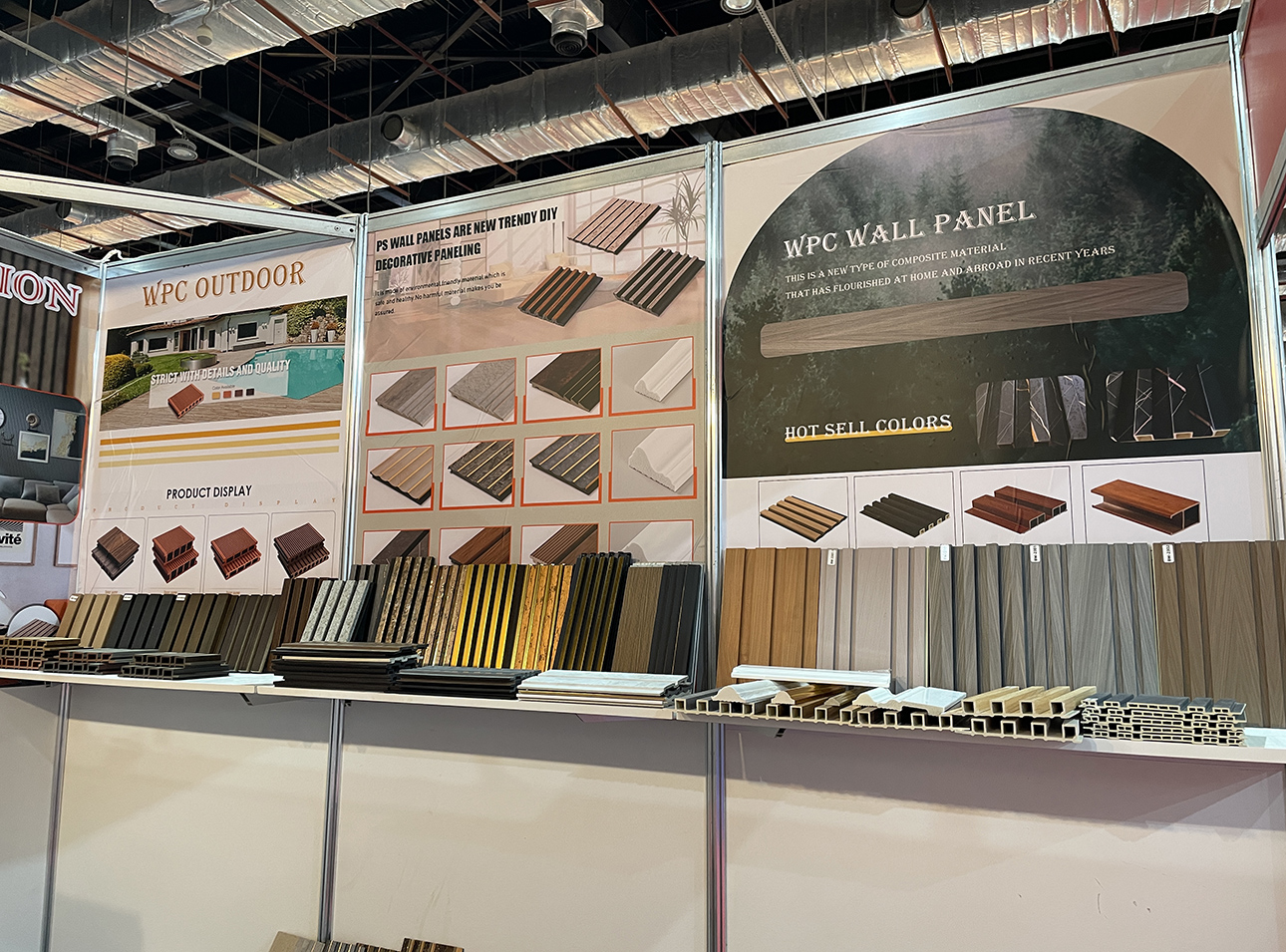

company exhibition